China Valve Manufacturer

Leading China's valve manufacturing industry, our company boasts prestigious certifications including WRAS, EAC, ISO9001, CE, ACS, SGS, and BV, ensuring top-tier quality and global compliance.

About TFW VALVE

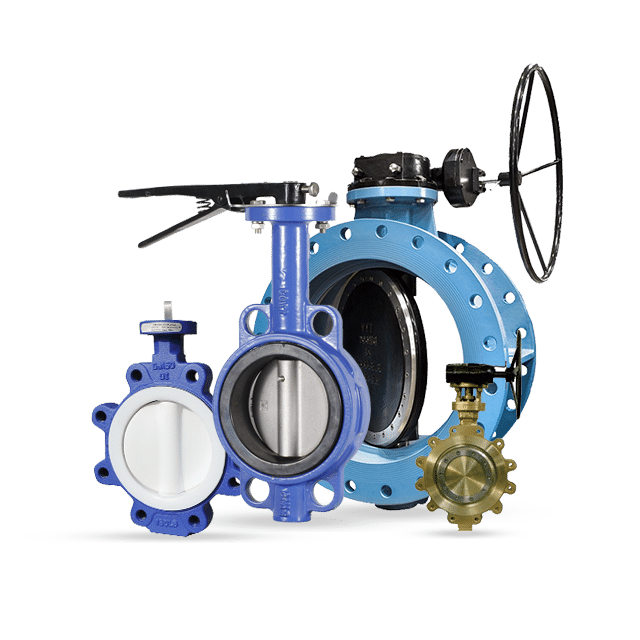

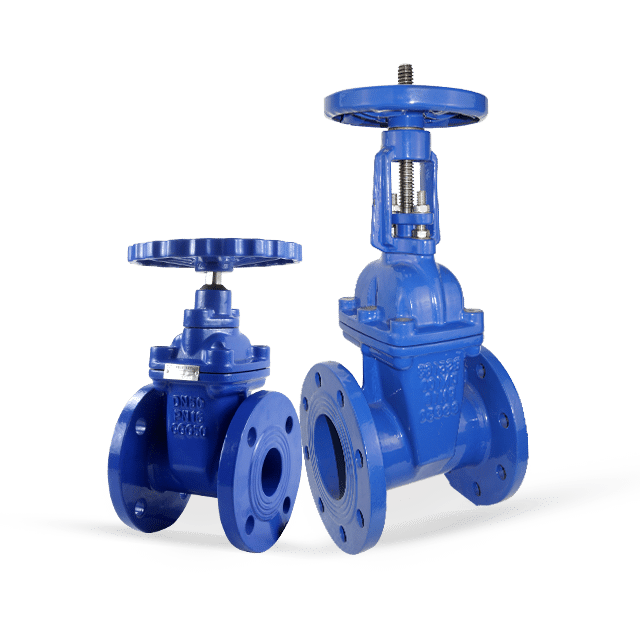

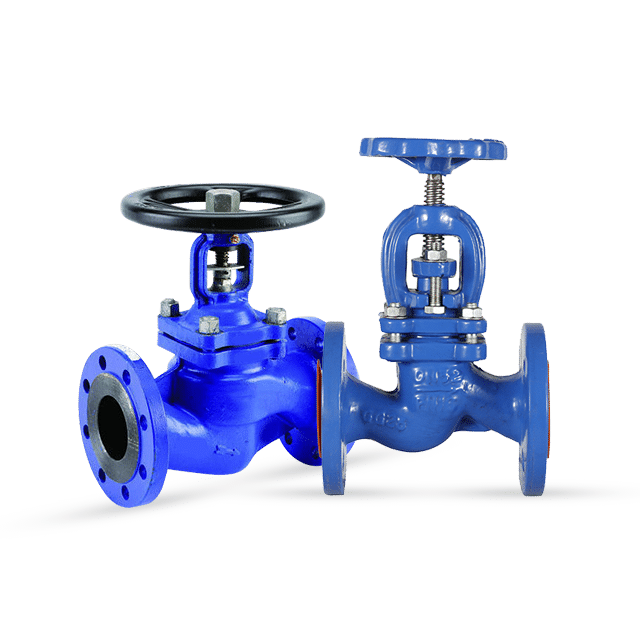

Tianjin Tangfa Watts Valve Co., Ltd.(TFW VALVE) was established in 2002 , registered capital of 10.8 million RMB. The company was formerly known as Tianjin Tangfa watts valve Sales Co., Ltd. TFW valve are mainly dedicated to the development, production and sales of medium and low pressure soft seal valves. The main products include: concentric butterfly valve, flange butterfly valve,metal seated butterfly valve, soft seal gate valve, hard seal gate valve, Gost gate valve,dual plate check valve, swing check valve, Y strainer and other products. The annual production capacity is over 8,000 tons.

Our Certificate

Video Center

0:16

0:16

0:16

Butterfly valve manufacturing workshop

Explore our advanced butterfly valve manufacturing workshop, equipped with the latest technology to ensure high-quality production. Our facility is designed for efficient workflow, featuring rows of newly crafted valves with durable construction and a striking blue finish. Our production adheres to strict quality standards, ensuring each valve is tested for functionality and longevity. Our team's expertise guarantees precision-engineered valves tailored to meet diverse industrial demands.

Gate valve manufacturing workshop

Our production line adheres to stringent quality control processes, guaranteeing that each valve meets global standards for performance and safety. Our skilled workforce is dedicated to delivering valves that provide unparalleled flow control solutions.

Testimonials

News Center

Regularly update valve knowledge and company latest news

Valve knowledge

Expert Insights into Butterfly, Gate, and Check Valves

Company news

Company news and latest developments

Latest news

Complete Guide to Butterfly Valve Disc Selection and Use

In the field of industrial fluid control, butterfly valves are widely used for their compact design, quick operation, and low flow resistance. At the heart of their performance lies the rotating “butterfly wing” at the center—the butterfly valve disc. Serving both as the gate that shuts off flow and the vane that regulates it, even

What material is used for butterfly valve seals?

Butterfly valves are widely used in industries such as water treatment, chemical processing, oil and gas, HVAC, and shipbuilding due to their compact design, easy operation, and cost-effectiveness. In these systems, the sealing performance of the valve directly impacts fluid control efficiency and the overall safety of the equipment. Why Butterfly Valve Seals Matter While

When to Use Concentric, Double-Offset, or Triple-Offset Butterfly Valves?

Have you ever faced this dilemma when purchasing butterfly valves? To cut costs, you chose the most economical concentric valve, only to end up with frequent leakage and higher maintenance expenses within just half a year. Or perhaps you selected a double-offset valve for a high-temperature pipeline, only to find the sealing materials deteriorating quickly,

Can Butterfly Valves Be Used for Flow Control?

In water supply networks, water treatment plants, HVAC systems, and other fluid-handling projects, engineers and procurement teams often ask: “Can a butterfly valve be used for flow control?” The answer isn’t a simple yes or no. A sound decision depends on understanding the valve’s characteristics and the specific operating conditions. This article takes a clear,

Understanding the Gate Valve Symbol in P&ID Diagrams

In municipal water supply, building water supply and drainage, and water treatment plant projects, the Gate Valve is one of the most common types of isolating valves. It is primarily used within pipelines as a fully open or fully closed shut-off device, ensuring the medium can pass through unimpeded or be completely blocked. However, in

Stainless Steel Butterfly Valve Material Guide: CF8, CF8M, 304, and 316

When purchasing stainless steel butterfly valves for water treatment, water supply systems, or fluid control projects, the stainless steel grades we are familiar with are typically 304, 316, etc. However, upon arrival at the site, we often find that the valve body nameplate does not display numerical identifiers such as ‘304’ or ‘316,’ but instead